Content of PetroWiki is intended for personal use only and to supplement, not replace, engineering judgment. SPE disclaims any and all liability for your use of such content. More information

The screen slot width is typically half the smallest gravel size selected but should not exceed 70% of the smallest grain diameter. While it may appear that this design is conservative, it will not restrict productivity and allows for variances in screen tolerances. Johnson Screens with its trade mark Vee-Wire ® is the leading brand for screens in industrial filters, water well and architecture. In 1904, Edward E. Johnson founded Johnson Screens after developing world’s first continuous slot wire wrapped screen to be used in a water well.

The slotted liner or screen is the mechanical device that contains the gravel-pack sand in an annular ring between it and the casing wall or open hole.

- 7Proprietary screen designs

Function of slotted liner or screen

Fig. 1 shows a schematic of the function of a slotted liner or screen in an openhole gravel pack.

Fig. 1—Openhole gravel-pack schematic.[1]

Slotted liners

Slotted liners are made from tubulars by saw-cutting slot configurations, as shown in Fig. 2. Slot widths are often referred to in terms of gauge. Slot or screen gauge is simply the width of the opening in inches multiplied by 1,000. For instance, a 12-gauge screen has openings of 0.012 in.

Fig. 2—Slotted-liner geometries (courtesy of Baker Oil Tools).

The machining consists of cutting rectangular openings with small rotary saws. Routine slot widths are 0.030 in. or larger. The minimum slot width that can be achieved is about 0.012 in. Slots that cut less than 0.020 in. in width involve high costs because of excessive machine downtime to replace broken saw blades that overheat, warp, and break.

The single-slot staggered, longitudinal pattern is generally preferred because the strength of the unslotted pipe is preserved. The staggered pattern also gives a more uniform distribution of slots over the surface area of the pipe. The single-slot staggered pattern is slotted with an even number of rows around the pipe with a typical 6-in. longitudinal spacing of slot rows.

The slots can be straight or keystone shaped, as illustrated in Fig. 3. The keystone slot is narrower on the outside surface of the pipe than on the inside. Slots formed in this way have an inverted “V” cross-sectional area and are less prone to plugging because any particle passing through the slot at the outside diameter (OD) of the pipe will continue to flow through, rather than lodging within the slot. While the slotted liners are usually less costly than wire-wrapped screens, they have smaller inflow areas and experience higher pressure drops during production. Slotted liners also plug more readily than screens; they are used where well productivity is small and economics cannot support the use of screens.

Fig. 3—Straight and keystone-shaped slots (courtesy of Baker Oil Tools).

The length of the individual slots is measured on the inside diameter (ID) of the pipe. Usual practice dictates 1½-in. long slots for slot widths of 0.030 in. and under, 2-in. long slots for slot widths between 0.030 to 0.060 in., and 2½-in. long slots for slot widths of 0.060 in. and larger. Slot width tolerance is generally ± 0.003 in. for widths of 0.040 in. and wider and ± 0.002 in. for widths less than 0.040 in.

The primary advantage of a slotted liner over wire-wrapped screens is usually cost; however, small gauge, high-density slot patterns may cost as much as wire-wrapped screens. The disadvantages of the slotted liner are:

- limited flow area (2 to 3%, creating a low tolerance to plugging)

- minimum available slot size (approximately 0.012 in.).

Slot widths that are less than 0.020 in. and cut in standard carbon steel-pipe grades can rust and will either close or reconfigure the slot opening so that they do not function properly unless they are coated, protected, or stored indoors before use.

Wire-wrapped screens

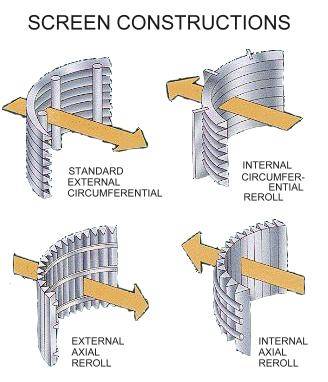

Wire-wrapped screens offer another alternative for retaining the gravel in an annular ring between the screen and the formation. Wire-wrapped screens have substantially more inflow area than a slotted liner, as Fig. 4 illustrates. The screen consists of an outer jacket that is fabricated on special wrapping machines that resemble a lathe. The shaped wire is simultaneously wrapped and welded to longitudinal rods to form a single helical slot with any desired width. The jacket is subsequently placed over and welded at each end to a supporting pipe base (containing drilled holes) to provide structural support. This is a standard-commodity design manufactured by several companies. A schematic of the screen construction is shown in Fig. 5. Screen tolerances are typically plus 0.001 and minus 0.002 in.; hence, a specified 0.006-in. slot could vary in slot width from 0.004 to 0.007 in.

Fig. 4—Comparison of effective inlet areas (20-gauge screen).[1]

Fig. 5—Wire-wrapped screen (courtesy of Baker Oil Tools).

Because these designs have been used for more than 40 years in worldwide oilfield operations, a great deal is known about the performance of wire-wrapped screens. The typical pipe-base screen fabrication consists of a grade 316L stainless steel jacket placed over a N-80 pipe base; however, other metals can be specified as required for site-specific applications. The inflow area of screens varies from about 6 to 12% (or higher), depending on the slot opening. Screens with the smallest slot openings are typically 6 gauge (0.006 in.). For large gravel, 10 to 20 mesh, screen slot openings are about 18 gauge (0.018 in.).

A version of the wire-wrapped screen is the rod-based screen that consists of the jacket only; however, rod-based screens may have additional heavier rods and a heavier wire wrap than the jackets used on pipe-base screens to provide additional strength. Rod-based screens are commonly used in shallow water-well completions that typically range from a few hundred to maybe a 1,000 ft in depth. Hence, they do not require the strength that is gained by installing the screen jacket over a pipe base. Screen diameters range from 1.5 to 7 in. in diameter (or larger). This is the diameter of the pipe base. The actual screen diameter is slightly larger (i.e., the actual OD of a 3.5-in. screen is about 4 in.).

Prepacked screens

Prepacked screens are a modification of wire-wrapped screens; they actually represent a modular gravel pack. They consist of a standard screen assembly with a layer of resin-coated gravel (consolidated) placed around it that is contained in an annular ring supported by a second screen (dual-screen prepack) or outer shroud (single-screen prepack). The resin coating is a partially cured phenolic plastic. Being dry, the resin-coated gravel can be handled like ordinary gravel. After prepacking the screen, the complete unit is heated to cure and harden the resin. The thickness of the gravel layer can be varied to meet special needs. The screens with the lowest profiles are those that contain an annular pack between the jacket and the pipe base. This screen has a thin lattice screen wrapped around it to prevent gravel from flowing through the drill holes in the pipe base before consolidation.

Examples of prepacked screens are in Fig. 6. Prepacked screens have been used with gravel packs instead of standard wire-wrapped screens and in stand-alone applications in horizontal wells. While the prepacked screens have been used in stand-alone service, experience has shown that they are highly prone to plugging, consequently restricting productivity. The inflow area of these screens is about 4 to 6% of the surface area. The exact amount depends on the slot opening and the size of the gravel.

Fig. 6—Types of prepacked screens (courtesy of Baker Oil Tools).

Flow capacities of screens and slotted liners

Fig. 7 shows the pressure drop associated with commercial wire-wrapped screens. Because all have similar designs, there is little difference in performance from one manufacturer to another. These flow capacity tests were performed using water containing no plugging material. The data indicate that all screens have exceptionally high flow capacities. Flow testing with slotted liners revealed that their flow capacity was related to the slot density rather than the screen diameter. Their flow capacities are typically less than half that of wire-wrapped screens with the same diameter. Note that the flow rates were measured in increments of B/D/ft of screen. For flow rates that are typical of most wells, the pressure loss through the screen is negligible, provided that they are not plugged. Slotted liners are more easily plugged than wire-wrapped screens because the slots are usually cut parallel to each other. On the other hand, wire-wrapped screens are fabricated with keystone-shaped wire that allows a particle to pass through the screen if it can traverse the minimum restriction at the OD of the screen. The keystone design can be observed in Fig. 3.

Fig. 7—Flow capacity of 12-gauge screens with 20/40 U.S. mesh gravel.[1]

Tensile collapse strengths of wire wrapped and prepacked screens

Tensile strength test results performed on screens and slotted liners in standard testing equipment showed that standard pipe-base screens have higher tensile ratings than rod-base screens. Testing demonstrated that yielding occurred in the pipe body as well as the coupling. As a consequence, when yielding in the connection caused a thread to separate, the test was terminated. The tensile strength of standard pipe-base screens was about twice that of the rod-base screens.[1] For conservative designs, the tensile strength should be the lesser of 65% of the pipe body or the published joint pull-out strength.

Individual tests demonstrated collapse failures as high as 6,000 to 9,000 psi; however, this represented the simultaneous failure of the screen and the pipe base; screens have a collapse rating of about 3,500 psi, which is the rating for the jacket.

Proprietary screen designs

Proprietary designs were originally developed for stand-alone installations in horizontal wells rather than a gravel-packed completion; however, gravel-pack screen applications should not be ruled out. They are also applicable in this service. Proprietary designs are premium designs that surpass the performance of either a standard wire-wrapped screen or a prepacked screen in their ability to resist plugging and erosion and are equipped with torque-shouldered connections to permit rotation.

Because horizontal completions typically consist of a thousand to several thousand feet of completion interval, the main issue is the susceptibility of a particular design to plug with time rather than the flow capacity. These new designs have increased inflow areas to as much as 30% of the surface area of the screens. The materials used and the designs differ from conventional wire-wrapped screens. They consist of designs with the following materials:

- Lattice

- Dutch weave

- Porous membrane

- Sintered metal

- Corrugated weave

The logic used in these designs was that because these screens have inflow areas of 30% compared to about 5% with prepacked screens, their longevity should be extended by about a factor of six when operating under similar downhole conditions. Other issues involve the ability to run the screen without creating damage that would either prevent sand control or restrict productivity. To address this concern, most of the proprietary designs have an outer shroud to protect the screen during installation. Proprietary connections are typically used for horizontal service because of their high strength and the ability to rotate if necessary.

Sintered metal screens

The sintered metal screen design was initiated in gravel-pack use in about 1990. The design consists of placing a sintered metal sleeve that is 0.15 to 0.25 in. thick over a drilled pipe base. The sintered metal sleeve contains approximately 30% flow area. The sleeve acts as the filtration medium, while the pipe base provides tensile strength and collapse resistance. Fig. 8 is a schematic of the screen design.

Fig. 8—Sintered metal screen schematic (courtesy of Baker Oil Tools).

Tensile strength and collapse resistance of this design should be about the same as that for wire-wrapped screens. For conservative designs, the tensile strength capabilities should be the about 65% or the lesser of either the published pipe strength or the joint pull-out of the coupling. The collapse rating should be similar to published values for wire-wrapped screens of about 3,500 psi.

Porous metal membrane screens

This screen design consists of multiple layers (3 or 4) of porous metal membrane (PMM), which contains about 30% open area through variable-sized pore openings. These are between an underlying drainage and overlying protecting mesh screen. They are placed concentrically between a drilled pipe base and a perforated outer shroud. The filter medium for the screen is sintered metal powder that is pressed against a stainless steel lattice screen to provide structural support for the filtration medium. A schematic of the screen’s construction is illustrated in Fig. 9.

Fig. 9—Porous metal membrane screen schematic (courtesy of Baker Oil Tools).

Test data from the manufacturer show tensile strength testing performed to 110k lbf and a collapse test to about 7,000 psi performed on 2 7/8-in. screens, both of which reflect the strength of the pipe base. These data are similar to values for commodity wire-wrapped screens. The tensile strength rating should be less than 65% of the pipe body or connection because physical properties of the screen jacket and perforated shroud should not contribute to these properties significantly.

Shrouded multilayer screens

This screen design consists of three layers of media that form the jacket, which are placed concentrically around a drilled pipe base. The base wrap for the jacket consists of a round stainless steel wire-wrapped support that serves as a drainage layer for the overlying filtration medium. The shroud is placed concentrically over the filtration medium. See Fig. 10 for a schematic of the design.

Fig. 10—Shrouded multilayer screen (courtesy of Baker Oil Tools).

The purpose of the base wrap or inner jacket is for support for the overlying filtration medium against high differential pressure. The wrap also promotes using the entire surface area of the filtration medium that optimizes plugging resistance. The openings in the base wrap are typically about 25 microns or larger than the filtration medium to provide secondary sand control. The filtration medium provides pore throat openings that assist in maximizing the inflow area that develops a more permeable filter cake. The design of the filtration medium, a Dutch weave, redirects the flow through it to minimize erosion and extend screen life. The design being offered is rated at a uniform pore-throat opening sizes from 110 to 230 microns. The inflow area for this design is also about 30% of the surface area of the screen. The outer shroud protects the inner filtration section during installation in the well and assists in redirecting the flow stream during production so that erosion of the filtration section is minimized. The strength rating for this screen is a tensile rating of 65% of the pipe body or the published joint pull-out strength and a jacket collapse rating of 3,500 psi.

Plugging and erosion tests on screens

Prepacked screen designs are more susceptible to plugging than other designs. This stems from their depth filter design. Standard wire-wrapped screens are a surface filter, which are not as susceptible to plugging but are more prone to erosion. Certain proprietary designs are better at resisting plugging and erosion than others. The best designs have large inflow areas and redirected flow through the screen to minimize erosion.

References

- ↑ 1.01.11.21.3Penberthy, W.L. Jr. and Shaughnessy, C.M. 1992. Sand Control, 1, 11-17. Richardson, Texas: Monograph Series, SPE.

Noteworthy papers in OnePetro

Use this section to list papers in OnePetro that a reader who wants to learn more should definitely read

External links

Use this section to provide links to relevant material on websites other than PetroWiki and OnePetro

See also

Category

Content of PetroWiki is intended for personal use only and to supplement, not replace, engineering judgment. SPE disclaims any and all liability for your use of such content. More information

A gravel pack is simply a downhole filter designed to prevent the production of unwanted formation sand. The formation sand is held in place by properly sized gravel pack sand that, in turn, is held in place with a properly-sized screen. To determine what size gravel-pack sand is required, samples of the formation sand must be evaluated to determine the median grain size diameter and grain size distribution.[1] The quality of the sand used is as important as the proper sizing. The American Petroleum Institute (API) has set forth the minimum specifications desirable for gravel-pack sand in API RP 58, Testing Sand Used in Gravel-Packing Operations.[2]

- 1Formation sand sampling

Formation sand sampling

The first step in gravel-pack design is to obtain a representative sample of the formation. Failure to analyze a representative sample can lead to gravel packs that fail because of plugging or the production of sand. Because the formation sand size is so important, the technique used to obtain a formation sample requires attention. With knowledge of the different sampling techniques, compensation can be made in the gravel-pack sand size selection, if necessary.

Produced samples

A produced sample of the formation sand is easily contaminated before it reaches the surface. Although such a sample can be analyzed and used for the gravel-pack sand size determination, produced samples will probably have a smaller median grain size than the median of actual formation sand. The well’s flow rate, produced fluid characteristics, and completion tubular design influence whether a particular size is produced to surface or settles to the bottom of the well. In many cases, the larger sand grains settle, so a sample that is produced to the surface has a higher proportion of the smaller-size sand grains. This is the reason that the surface sample is not a good representation of the various sizes of formation sand. Also, the transport of sand grains, through the production tubing and surface flow lines, may result in broken sand grains, causing the presence of more fine and smaller grains.

Bailed samples

Samples collected from the bottom of a well using wireline bailers are also relatively easy to obtain, but these too are probably unrepresentative of the size of the actual formation sand. Bailed samples are generally biased to the larger-size sand grains, assuming that more of the smaller grains are produced to surface. Bailed samples also may be misleading in terms of grain size distribution. When closing the well in to obtain a sample, the larger sand grains settle to the bottom of the well first, and the smaller sand grains fall on top of the larger ones. This results in a sorting of the formation sand grains into a sample that is not representative the formation sand. The use of bailed samples may result in the design of larger than required gravel-pack sand that can result in sand production (small formation particles passing through the gravel pack) or plugging of the gravel pack (small formation particles filling the spaces between the gravel-pack sand grains).

Sidewall core samples

Sidewall core samples are obtained by shooting hollow projectiles from a gun lowered into the well on an electric line to the desired depth. The projectiles remain attached to the gun with steel cables, so that when the gun is pulled from the well, the projectiles are retrieved with a small formation sample inside. Taking sidewall core samples is generally included in the evaluation stages of wells in unconsolidated formations; these are the most widely used sample types for gravel-pack sand design. Although more representative than produced or bailed samples, sidewall core samples can also give imprecise results because the volume in each sidewall sample is small. When the projectiles strike the face of the formation, localized crushing of the sand grains occurs, producing broken sand grains and generating more fine particles. The core sample also contains drilling mud solids that can be mistaken for formation material. Experienced lab analysts can separate the effects of crushing and mud solids prior to evaluating the sample, thus improving the quality of the results.

Well Screen Slot Sizes

Conventional core samples

The most representative formation sample is obtained from conventional cores. In the case of unconsolidated formations, rubber sleeve conventional cores may be required to assure sample recovery. Although conventional cores are the most desirable formation sample, they are not readily available in many wells because of the cost of coring operations. Coring in sand-producing formations is also plagued with poor recovery. If available, small plugs can be taken under controlled circumstances at various sections of the core for a complete and accurate median formation grain size and grain-size distribution determination.

Other samples

From time to time, operators have no formation sample. In this event, rely on any of the samples from offset wells. If the formation of interest has gravel-pack completions in nearby fields, rely on these. If there is still no information, select a relatively small gravel that will control most formation sand, or consult an expert.

Sieve analysis

Well Screen Slot Size Table

A sieve analysis is a laboratory routine performed on a formation sand sample for the selection of the proper-sized gravel-pack sand. A sieve analysis consists of placing a formation sample at the top of a series of screens that have progressively smaller mesh sizes downwards in the sieve stack. After placing the sieve stack in a vibrating machine, the sand grains in the sample will fall through the screens until encountering a screen through which certain grain sizes cannot pass because the openings in the screen are too small. By weighing the screens before and after sieving, the weight of formation sample, retained by each size screen, can be determined. The cumulative weight percent of each sample retained can be plotted as a comparison of screen mesh size on semilog coordinates to obtain a sand size-distribution plot, as shown in Fig. 1. Reading the graph at the 50% cumulative weight gives the median formation grain size diameter. This grain size, often referred to as d50, is the basis of gravel-pack sand size-selection procedures. Table 1 provides a reference for mesh size vs. sieve opening.

Fig. 1—Sand size distribution plot from sieve analysis.[3]

Table 1

If possible, a sample should be taken every 2 to 3 ft within the formation, or at least at every lithology change. The minimum size of the formation sample required for sieve analysis is 15 cm3. Sieving can be performed either wet or dry. In dry sieving (the most common technique), the sample is prepared by removing the fines (i.e., clays) and drying the sample in an oven. If necessary, the sample is ground with a mortar and pestle to ensure individual grains are sieved rather than conglomerated grains. The sample is then placed in the sieving apparatus that uses mechanical vibration to assist the particles in moving through and on to the various mesh screens. Wet sieving is used when the formation sample has extremely small grain sizes. In wet sieving, water is poured over the sample while sieving to ensure that the particles do not cling together.

Gravel pack sand sizing

Monitoring Well Screen Slot Size

There have been several published techniques for selecting a gravel-pack sand size to control the production of formation sand. The most widely used sizing criterion1 provides sand control when the median grain size of the gravel-pack sand, D50 , is no more than six times larger than the median grain size of the formation sand, d50 . The upper case D refers to the gravel, while the lower case refers to the formation sand. The basis for this relationship was a series of core flow experiments in which half the core consisted of gravel-pack sand and the other half was formation sand. The ratio of median grain size of the gravel-pack sand and median grain size of the formation sand was changed over a range from 2 to 10 to determine when optimum sand control was achieved.

The experimental procedure consisted of measuring the pack permeability with each change in gravel size and comparing it to the initial permeability. If the final permeability was the same as the initial permeability, it was concluded that effective sand control was achieved with no adverse productivity effects. If the final permeability was less than the initial permeability, the formation sand was invading and plugging the gravel-pack sand. In this situation, sand control may be achieved, but at the expense of well productivity.

Fig. 2 illustrates the results of core flow experiments for a particular gravel/sand combination. As shown in the plot, the permeability of the pack increases up to a median gravel/sand size ratio of 6 but decreases as the ratio increases further. The permeability decreases to a minimum as a 10:12 ratio is reached; then, it increases. The explanation for this behavior is that the permeability increases as the gravel/sand size ratio increases up to a ratio of about 6, which reflects the increasing permeability of the larger gravel (i.e., at a gravel/sand ratio of one, the gravel is the same size as the formation sand). At a gravel/sand size ratio of 6, the formation sand grains bridge on, rather than into the pore structure of the gravel, which is the correct gravel size that provides the highest permeability. However, as the gravel size becomes larger and the ratio increases, the formation begins to bridge within the pore structure of the gravel, thereby decreasing the pack permeability. At a ratio of 10:12, the formation sand has moved well into the pores, decreasing the permeability substantially. As the gravel becomes larger, a reversal occurs because now the formation sand can move both into and through the pore structure of the gravel. At ratios in excess of 15, the formation sand can flow through the gravel with ease. As Fig. 2 indicates, at gravel/sand ratios less than 10:12, there is sand control, whereas at ratios larger than 12, there is no sand control.

Fig. 2—Effect of gravel-sand ratio on sand control permeability.[3]

In practice, the proper gravel-pack sand size is selected by multiplying the median size of the formation sand by 4 to 8 to achieve a gravel-pack sand size range, in which the average is six times larger than the median grain size of the formation sand. Hence, the gravel pack is designed to control the load-bearing material; no attempt is made to control formation fines that make up less 2 to 3% of the formation. This calculated gravel-pack sand size range is compared to the available commercial grades of gravel-pack sand. Select the available gravel-pack sand that matches the calculated gravel-pack size range. In the event that the calculated gravel-pack sand size range falls between the size ranges of commercially available gravel-pack sand, select the smaller gravel-pack sand. Table 2 contains information on commercially available gravel-pack sand sizes.

Table 2

Note that this technique is based solely on the median grain size of the formation sand with no consideration given to the range of sand grain diameters or degree of sorting present in the formation. The sieve analysis plot, discussed earlier, can be used to obtain the degree of sorting in a particular formation sample. A near vertical sieve analysis plot represents good sorting (most of the formation sand is in a very narrow size range) vs. a highly sloping plot, which indicates poorer sorting as illustrated by curves “A” and “D,” respectively, in Fig. 1. A sorting factor, or uniformity coefficient, can be calculated as

Well Screen Slot Size

....................(1)

where

- Cμ = sorting factor or uniformity coefficient,

- d40 = grain size at the 40% cumulative level from sieve analysis plot,

- d90 = grain size at the 90% cumulative level from sieve analysis plot.

If Cμ is less than 3, the sand is considered well sorted (uniform); from 3 to 5, it is nonuniform, and if greater than 5, it is highly nonuniform.

Gravel pack sand

The productivity of a gravel-packed well depends on the permeability of the gravel-pack sand and how it is placed. To ensure maximum well productivity, one should use high quality gravel-pack sand. API RP 58, Testing Sand Used in Gravel Packing Operations, establishes rigid specifications for acceptable properties of sands used for gravel packing. These specifications focus on ensuring the maximum permeability and longevity of the sand under typical well production and treatment conditions. The specifications define minimum acceptable standards for:

- Size and shape of the grains

- Amount of fines and impurities

- Acid solubility

- Crush resistance

Only a few naturally occurring sands are capable of meeting the API specifications without excessive processing. These sands are characterized by their high quartz content and consistency in grain size. Table 3 gives the permeability of common gravel-pack sand sizes conforming to API RP 58 specifications (data from Sparlin, Gurley, and Cocales).[4][5][6]

Table 3

Once the sieve analysis has been performed and plotted, the remainder of the gravel-pack sizing can be performed graphically. The gravel-pack sand size is determined by multiplying the median formation grain size by 6. This value is the median gravel grain size. With a straight edge, construct the gravel curve so that its uniformity coefficient, Cμ, is 1.5. The actual gravel size can be determined by the intercept of gravel curve with the 0 and 100 percentile values. Select to the nearest standard gravel size. The screen slot width is typically half the smallest gravel size selected but should not exceed 70% of the smallest grain diameter. While it may appear that this design is conservative, it will not restrict productivity and allows for variances in screen tolerances. The diameter of the screen should allow for at least 0.75-in. clearance from the casing inside diameter (ID). Fig. 3[3] is an example gravel-pack design.

Fig. 3—.Effect of gravel-sand size ratio on sand control and productivity.[3]

Gravel pack sand substitutes

Although naturally occurring quartz sand is the most common gravel-pack material, many alternatives exist. These include:

- Resin-coated sand

- Garnet

- Glass beads

- Aluminum oxides

Each of these materials offers specific properties that are beneficial for given applications and well conditions. The cost of the materials ranges from 2 to 3 times the price of common quartz sand.

Nomenclature

| Cμ | = | sorting factor or uniformity coefficient |

| d40 | = | formation sand diameter, 40 percentile |

| d90 | = | formation sand diameter, 90 percentile |

References

- ↑Saucier, R.J. 1974. Considerations in Gravel Pack Design. J Pet Technol 26 (2): 205-212. SPE-4030-PA. http://dx.doi.org/10.2118/4030-PA

- ↑API RP 58, Recommended Practice for Testing Sand Used in Gravel Packing Operations, first edition. 1986. Washington, DC: API.

- ↑ 3.03.13.23.3Penberthy, W.L. Jr. and Shaughnessy, C.M. 1992. Sand Control,Vol. 1, 11-17. Richardson, Texas: Monograph Series, SPE.

- ↑Sparlin, D.D. 1974. Sand and Gravel - A Study of Their Permeabilities. Presented at the SPE Symposium on Formation Damage Control, New Orleans, Louisiana, 30 January-2 February 1974. SPE-4772-MS. http://dx.doi.org/10.2118/4772-MS

- ↑Gurley, D.G., Copeland, C.T., and Hendrick Jr., J.O. 1977. Design, Plan, and Execution of Gravel-Pack Operations for Maximum Productivity. J Pet Technol 29 (10): 1259-1266. SPE-5709-PA. http://dx.doi.org/10.2118/5709-PA

- ↑Cocales, B. 1992. Optimizing Materials for Better Gravel Packs. World Oil (December): 73.

Noteworthy papers in OnePetro

Pvc Well Screen Slot Sizes

Use this section to list papers in OnePetro that a reader who wants to learn more should definitely read

External links

Use this section to provide links to relevant material on websites other than PetroWiki and OnePetro